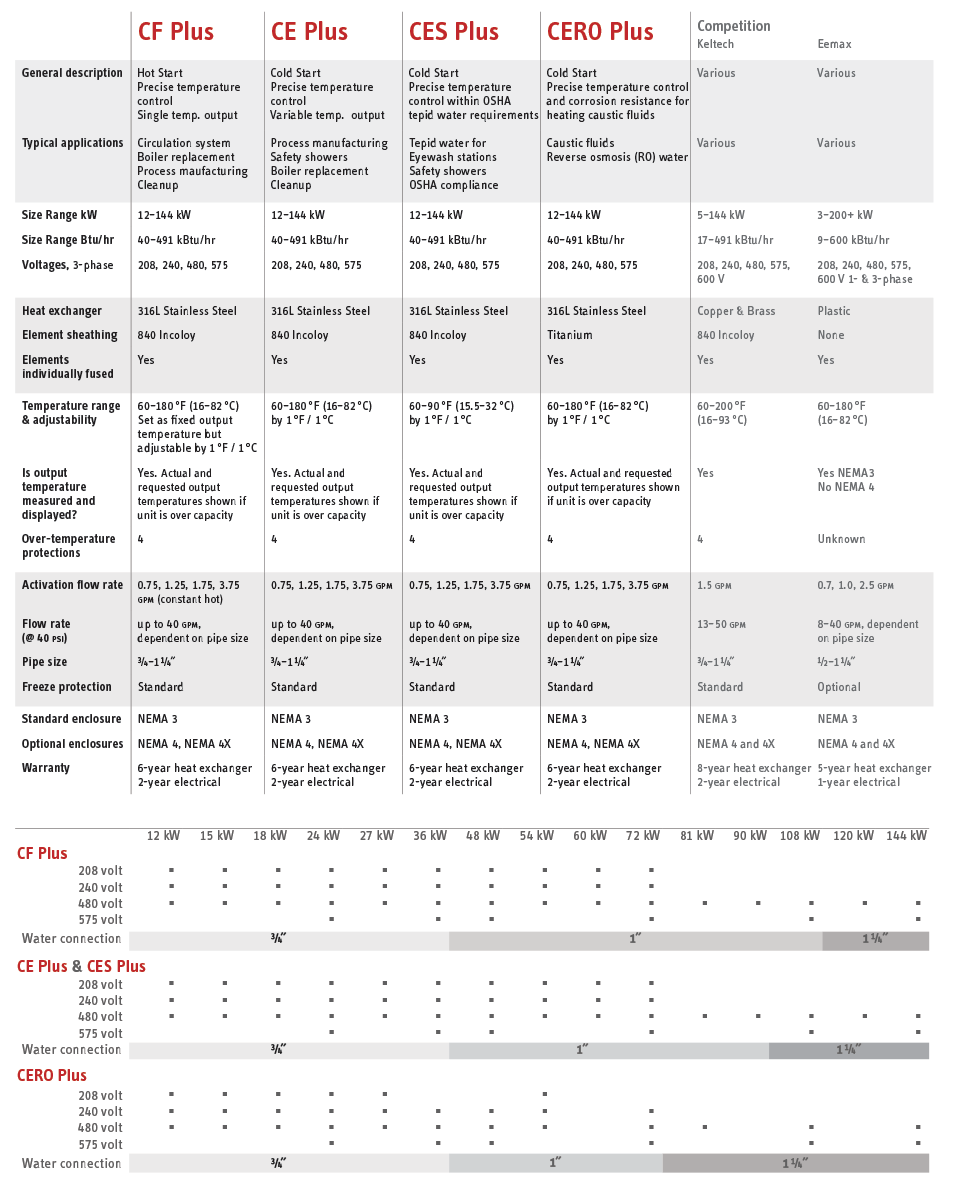

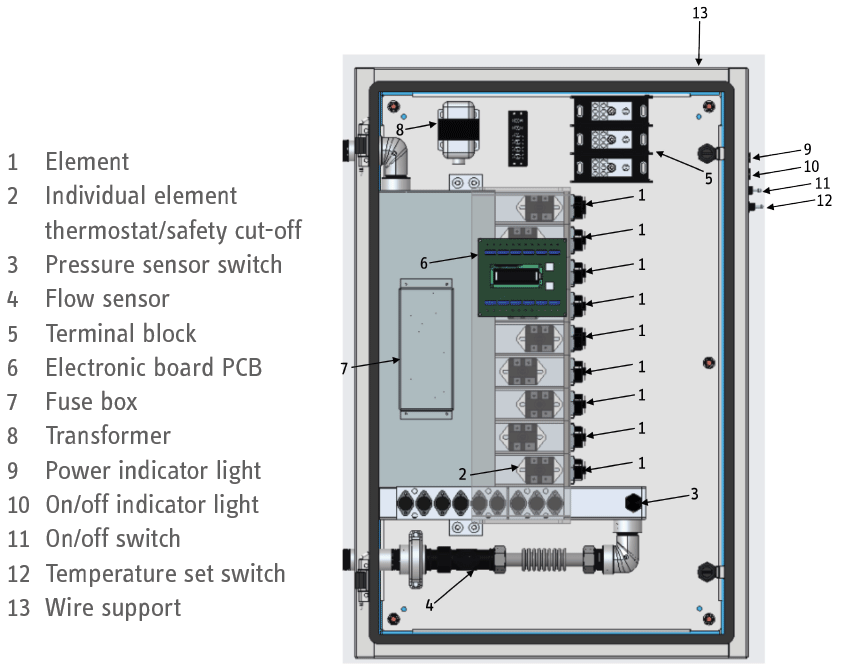

Shown: CERO Plus, 48 – 72 KW models configuration, standard NEMA 3 enclosure

Designed for reverse osmosis (RO) water & caustic fluid heating

CERO Plus models are designed to heat reverse osmosis (RO) water and caustic fluids. They have corrosion-free titanium-sheathed elements that will last longer in a caustic environment than standard Incoloy-sheathed elements. CERO Plus has the same electronic operation as the CE Plus series, calculating the amount of energy needed to meet hot water demand, then activating the minimum number of elements necessary to satisfy that demand, depending on flow rate and temperature measurement. No energy is used when the unit is idle other than the indicator light.

C Series overview

C Series 3-phase electric tankless water heaters are designed to provide hot water for commercial and industrial use. Tankless water heaters do not store hot water as a tank water heater does, but make it on demand as it is needed. There are several major benefits of tankless water heaters over tanks because of this difference.

First, a tankless water heater never runs out of hot water. As long as it is needed, a tankless water heater will make and deliver hot water at the specified set point temperature. Second, tankless water heaters are not storing hot water, and they have no standby heat losses. This results in energy savings on the order of 20% over an electric tank. The exception is hot start tankless models like our CF Plus, but their standby heat loss is minimal when compared to the extensive surface area of a standard tank. And third, tankless water heaters are considerably smaller than a tank, saving space, and are not prone to leakage. Our electric tankless water heaters also do not need venting.

C Series common features

Fabrication & enclosures

- All machining, welding, assembly, and testing done in Sarasota, Fla.

- Each unit is tested at full and partial load amp draw to ensure measurement accuracy and proper operation

- Standard NEMA 3 enclosure is hinged so cover and one side swing open for service access and element replacement. All components are intuitively laid out and designed, including element replacement without removing the heat exchanger.

- NEMA 4 and NEMA 4X watertight enclosures available if required

Plumbing

- Unique water flow relieves air build-up for increased longevity

- Best-in-class low pressure drop. See charts on website for details

- Heat exchangers and pipe connections are 316L stainless steel

- Inlet and outlet stub piping with ball valves included and pre-installed

- Lead-free brass pressure relief valve and air vent included

- ¾˝, 1˝, & 1 ¼˝ female water connection sizes depending on heating capacity

Electronic control

- “3i” is Stiebel Eltron’s closed loop control circuit with measurement of flow rate, inlet temperature, and outlet temperature

- The amount of energy needed to meet demand is electronically controlled so only the minimum number of elements necessary to satisfy demand are activated

- All models electronically flow activated using a vortex flow sensor available in 4 sizes, DN 10, 15, 20, 25, for customization to individual application

- Completely pre-wired with only mains power connection needed

- Printed circuit board (PCB), including triac driver, protected by Metal Oxide Varistor (MOV) against high voltage spikes from AC mains power

- Printed circuit board (PCB) optimized to provide safety for triac control

- Triac cooling accomplished with massive aluminum plate for reliability

Safety

- Four over-temperature protections

- Latent heat protection though controller software eliminates timer switch

- Each heating element protected individually with dry-mounted, manually resettable temperature/safety cut-off providing greater safety and leak risk reduction than immersed bi-metal thermostat

- Pressure sensor provides dry-fire protection on all models